Inspection & Measurement Department

Inspection & Measurement

At First Metrology, our highly qualified engineers and technicians operate across a wide range of industrial sectors, providing professional inspection, testing, and measurement services for all types of equipment and installations.

We are dedicated to ensuring the reliability, precision, and safety of your operations through detailed evaluations and rigorous compliance checks.Our teams deliver comprehensive metrology and inspection solutions throughout Tunisia and internationally, supporting companies in sectors such as manufacturing, energy, construction, food, pharmaceuticals, and transportation.

Each intervention is performed in accordance with national and international standards, including ISO and other regulatory frameworks, guaranteeing full quality assurance and regulatory compliance.With First Metrology, you benefit from a trusted partner committed to technical excellence, fast response, and accurate results, helping your business maintain the highest standards of performance, safety, and reliability.

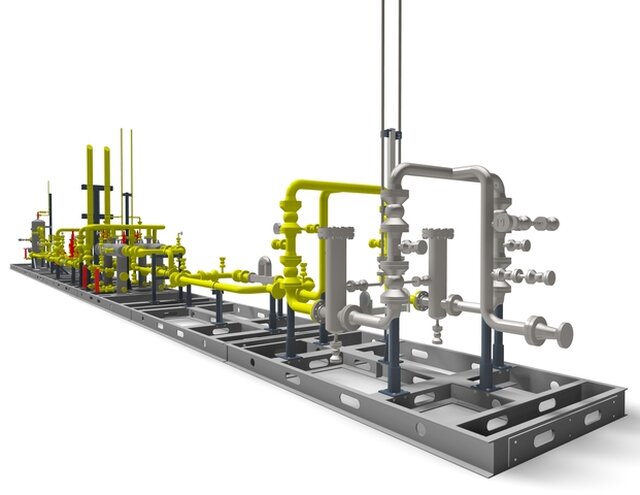

Gas network inspection

- Verification of technical files.

- Visual inspection of installations.

- Leak test of installations.

Electric Network Inspection

- Verification of compliance conforming the standards related to the exist installation.

- Inspection of electrical control panel.

- Verification of components of protection against thermal effects.

- Checking the choice of divers talking account of current allowable and tensions falls.

- Verification of protection devices, survey, and emergency shut off.

- Verification of potential equalization dielectric continuity test.

- Electrical separating measures and earthing.

- Low voltage motor control centre testing (IR…).

Pressure Vessel Inspection

Our engineers and technicians professionally inspect all kinds of pressure equipments and pressure installations, from the design phase to the manufacturing and operational phases.

Inspection of compressed air tanks

Our services:

- Steam boiler

- Valves

Pressure Vessel Inspection

- Wall thickness measurement and visit before hydrotest.

- Witness to mechanical tests, Visual & dimensional inspection

- Review and approved technical documentation: ITP, MPQT, Tally list, conformity certificates, Mill test certificate.

- Inspection of pressure vessels in services and in manufacturing workshop (at mill inspection)

- Witness to hydrotests

Electric Network Inspection

- Visual inspection of the characteristics of the lifting equipment and determination of its conformity with specified requirements where applicable.

- Dimensional check to show that the lifting equipment has neither permanent deformation, nor abnormality that would render incapable of being use safety for its designed purpose.

- General checking of the various components (slickline units, stroke limiters, brake shackles, wire rope, slings…).

Lifting Equipments Inspection

- Static and dynamic load test

- Check sizes of chain, egg links, rings, hooks, and make that they are suitable for the safe working load

- Visual inspection of structures and welding

- Non destructive Testing (MPI) for welded pad eyes before and after load test

Inspection of Pipeline

- Static and dynamic load test

- Check sizes of chain, egg links, rings, hooks, and make that they are suitable for the safe working load

- Visual inspection of structures and welding

- Non destructive Testing (MPI) for welded pad eyes before and after load test

Fire Fiting System Inspection

- Verification of prevention plans, the means to fight against fire and their compliance with regulations and standards

- Detection of established defects and measures insufficiencies for fighting against fire

- Monitoring the implantation of fire fighting equipments